Medical Device Design Verification Essentials

At some point in the new medical device development, design verification must be performed to satisfy the applicable regulations and standards such as:

21 CFR 820.30 Design Controls

(f) Design verification. Each manufacturer shall establish and maintain procedures for verifying the device design. Design ... continue reading

Process Validation For Electronic Medical Devices: Fundamental Things To Know

If you are an engineer involved with the manufacturing of medical devices you may be assigned to perform process validation, which is mandated by FDA regulations and the applicable international standards.

Let’s define process validation. Here is the FDA’s definition of process validation (21 CFR 820.3 Definitions): ... continue reading

How To Ensure Successful Installation Qualification (IQ) for Medical Devices

As part of process validation, IQ establishes the foundation for all other qualification activities. Its purpose is to ensure that manufacturing equipment has been correctly installed to meet the manufacturer’s specifications and that it will operate within the expected ranges. Depending on the product and manufacturing process, IQs will be different. An IQ for injection molding, pharmaceuticals, and the ... continue reading

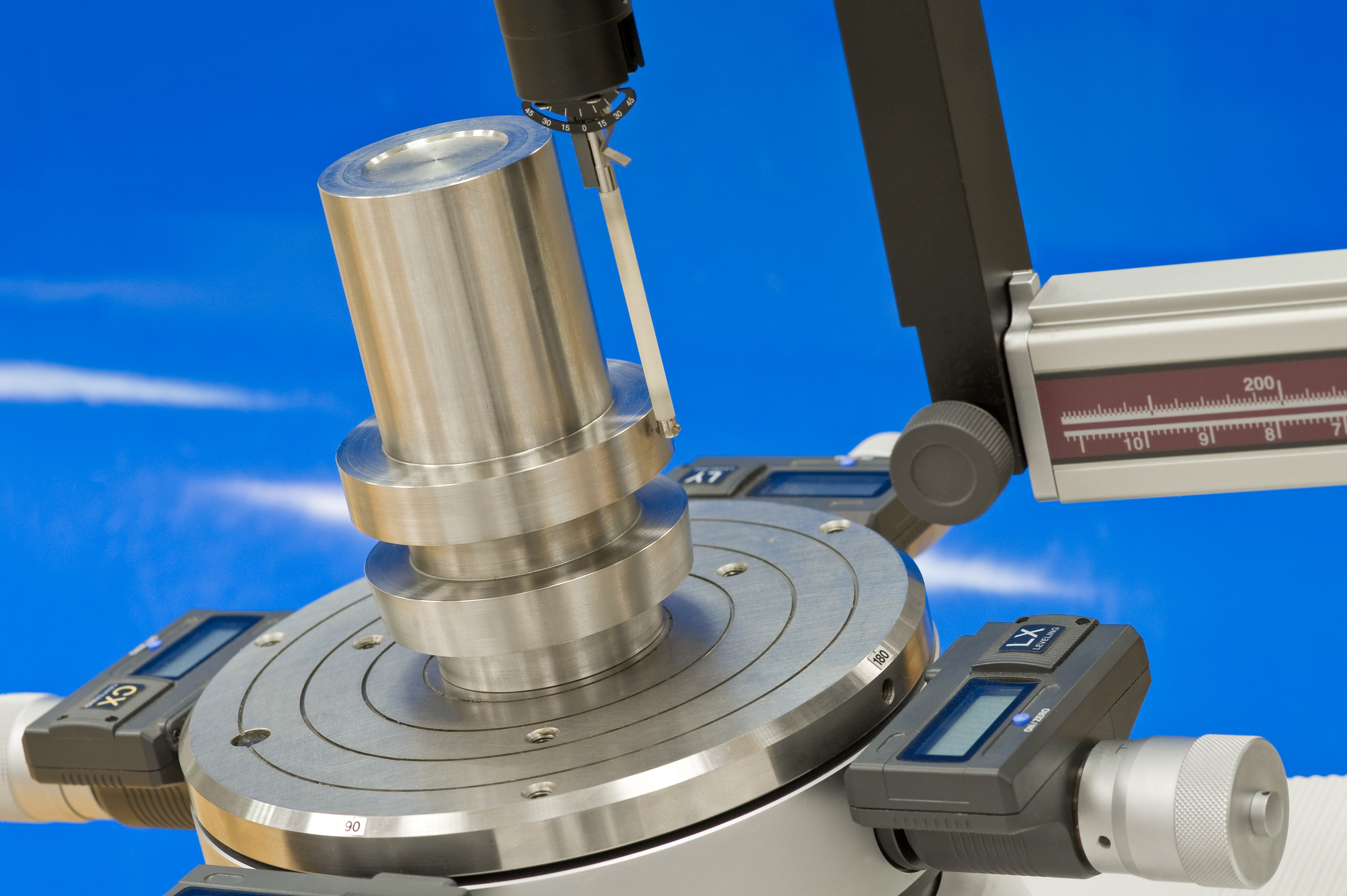

Important Things To Know When Performing Operational Qualification (OQ) For Medical Devices

As part of process validation, Operational Qualification (OQ) establishes process capability and proves that the output of the process is both predictable and understood and that the process is capable at its extremes. The purpose of OQ is to establish that: The process works, the process inputs are known and characterized ... continue reading

Resolving the Challenges of Failure Mode and Effects Analysis (FMEA) for Medical Devices

Without a doubt, medical device manufacturers face multiple challenges. Stringent regulations, intense competition, and accelerated product development cycles are just a few of the issues manufacturers must handle. However, effective risk management throughout the product's entire life cycle is undoubtedly paramount. Risk ... continue reading

Four Essential Steps for Successful Non-Destructive Test Method Validation

The test method validation (TMV) process usually starts with determining which test methods on a project need validation and which do not. Test methods needing validation are validated to confirm their fit and suitability for the intended purpose, performance to an acceptable level, and reliability over time. In other words, validation must demonstrate that the precision and accuracy limits are met with regard ... continue reading

How to Make Design Controls More Efficient With Traceability Matrix

If you are a manufacturer of Class III, Class II, and certain Class I medical devices, you must meet mandatory Food and Drug Administration requirements for design controls, namely 21 CFR 820.30. Companies that have ISO 13485 and/or ISO 9001 certifications must comply with design control requirements as well. Design controls are practices, policies, and procedures that formally govern the design and ... continue reading

Practical Tips to Eliminate Quickly CAPAs Backlog

While on CAPA remediation projects as a CAPA Coordinator with the task of reducing or eliminating severe backlogs as fast as possible, I came up with ways of improving CAPAs’ time to closure that I would like to share with you in this article.

Everything begins with the CAPA process. Although each company has its own CAPA policies and procedures, the basic steps ... continue reading